Analyze and define the manual task map. Basically this involves difficult issues like choosing suitable robots and placing them properly in the.

Lecture Work Cell Design Work Cell Design Important Considerations Work Cell Layout Changes To Other Equipment In Cell Multiple Machines And Robots Course Hero

Our typical robotic cell is a complete system that includes the robot controller and other peripherals such as application and safety equipment.

. Robot centered Cell 196. Part 2. The designing of robotic cells is the process of synergistic combining the.

5105 Power and force limiting by inherent design or control. Minimize motion Avoid unnatural postures and movements Avoid sharp turns in motion Make moves easy to perform without much concentration Use hands and forearms instead of upper arms and shoulders. Checking that all safeguards are in place and that work envelope is clear of personnel is critical.

Safety-Rated Monitored Stop. In a robotic application many times these goals are safety labor cost throughput or ergonomically-based. Employed to perform these activities.

The problem of designing robotic work cells has become a major field of research. A robot cell is a complete system that includes the robot controller and other peripherals such as a part positioner and safety environment. Inline robot cell 197.

Intermittent Transfer 2Continuous Transfer 3Non-Synchronous Transfer Intermittent TransferThe parts are moved in a start-and-stop motion from one station to another along the line. Challenges in robotic cell layout design and optimization Proper configuration for task While designing a robotic cell selecting the most suit-able robot for a given industrial operation is one of the most difficult assignments because of a wide range of physical forms such as cylindrical SCARA articu-. The entry gates we install on robot cells at Motion Controls Robotics consist of a locking gate switch and a yellow Request Access push button.

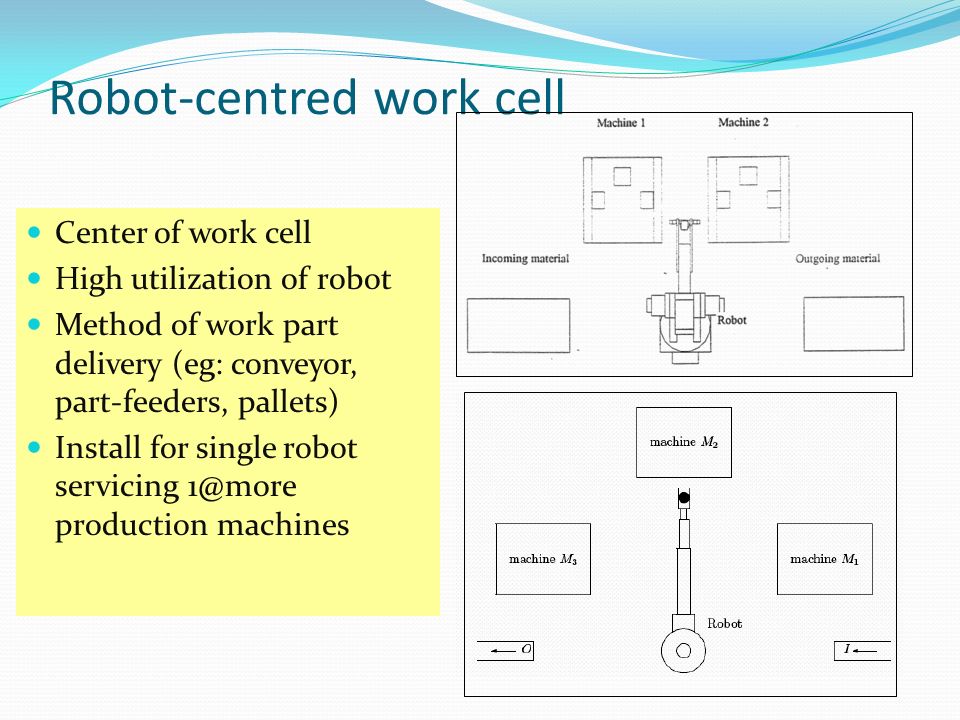

Most collaborative robot applications start off as a manual operation. An important technology for achieving this goal is robotic workcell simulation. These layouts are classified in to 3 basic types Robot centered cell Inline robot cell Mobile robot cell 195.

They feature a locking solenoid and an internal release to prevent an operator from becoming trapped inside the robot cell. Which purposely designed robots work in direct cooperation with a human within a defined workspace emphasis added. Turnkey cells are fully integrated pre-configured solutions.

They install in minimal time and offer the advantage of proven success. 02-Chapter 2-Part 1 Robot Work Cell Design and Controlpdf. Ergonomic Factors in Work Station and Product Design Design the work to.

If the control requirements to operate the cell are complicated a higher-level control device such. This type of switch is both TUV certified and RIA compliant. If the control requirements to operate the cell are simple and easy the robot controller is.

The control problem will be. Robots and associated peripheral devices. In this article I look to group the robotic cell layout development.

Robotic workcell that integrates a robotic manipulator a conveyor and a vision system. You have been asked by your supervisor to power up the robots controller. The idea here is to use your manual task as a starting point for the robotic cell.

2 ROBOT CELL LAYOUTS Work-cells can be organized into many different layouts. Work Cell Design and Control. Robot cells are sometimes referred to as workcells.

Chapter 5 Contents Robot Cell Layouts Multiple Robots and Machine Interface Some Consideration in Work Cell Design Interlocks Error Detection and Recovery Robot Cycle Time Analysis Introduction Step of a company to implement a robotics program in its operation. For light work Minimize lifting Follow a rhythm Cellular Flow. Robot cells are sometimes referred to as work cells.

You must make sure that all personnel and equipment are out of the workcell. Visually inspect the robot controller work cell and surrounding area. Robot cell design Robot work cell can be organised in to various arrangements or layouts.

Initial familiarization with the technology Plant survey to identical. It is also called synchronous transfer since all parts are moved simultaneously to the next stop. The four cell layout design steps are.

Once the system type is defined technical requirements are stated and the goals are established one of the most crucial ingredients to a successful project is an efficient system layout. The key features of the workcell are its portability modular design and relatively lo w cost. Triple Robotic Weld Cell with Rexroth weld controllers and MFDC weld guns with Nita tool changers AB Contrologix PLC AB Panelview 1500 solid 12ft x 5 ft frame table top tip dressers and weld gun stands all safeties easy loading of short run weld fixtures and can add QDC table top plates cell built on frames making them easier to install on your floor and ability to easily.

Robot systemcell and application. 1 WORK CELL DESIGN Important considerations Work-cell layout Changes to other equipment in cell Multiple machines and robots in cell Part position and orientation Part identification Protection of robot from environment Utilities Control of the work cell Safety. The final design showcases a number of emerging technologies equipment and.

Rapid design and deployment of a robotic workcell require the successful applications of concepts tools and methods for fast product design manufacturing process planning and plant floorcell control support. Holonomic robots of DOF is the same as of controllable DOFs nonholonomic robot of DOF is bigger then of controllable DOFs redundant robot of controllable DOF is larger then of total DOFs eg. Robot or robot work cell installation in terms of its design operation and control P2 explain the design principles of a given industrial robot or robot work cell M2 justify the use of a specific sensorend effector for a given industrial robot or robot work cell application D2 test that an industrial robot or robot work cell.

The subject of considerations presented in this work concerns the designing and simulation of a robotic work cell. An optimal robotic cell solution are summarized. You should begin by analyzing how human workers are currently performing the task.

Turnkey cells are fully integrated pre-engineered solutions. 54 There are 3 types of work part transport system used in in-line robot work cell.

Robot Work Cell Definition Types Safety Considerations Hvr Mag

Work Cell Design And Control Ppt Video Online Download

Robot Work Cell Design And Control Ppt Robot Work Cell Design And Control Chapter 5 1 Contents Robot Cell Layouts Multiple Robots And Course Hero

Robot Cell Layouts And Interlocks Pdf Pdf

Work Cell Design And Control Ppt Video Online Download

5 Robot Cell Design Principles Inlearc

0 comments

Post a Comment